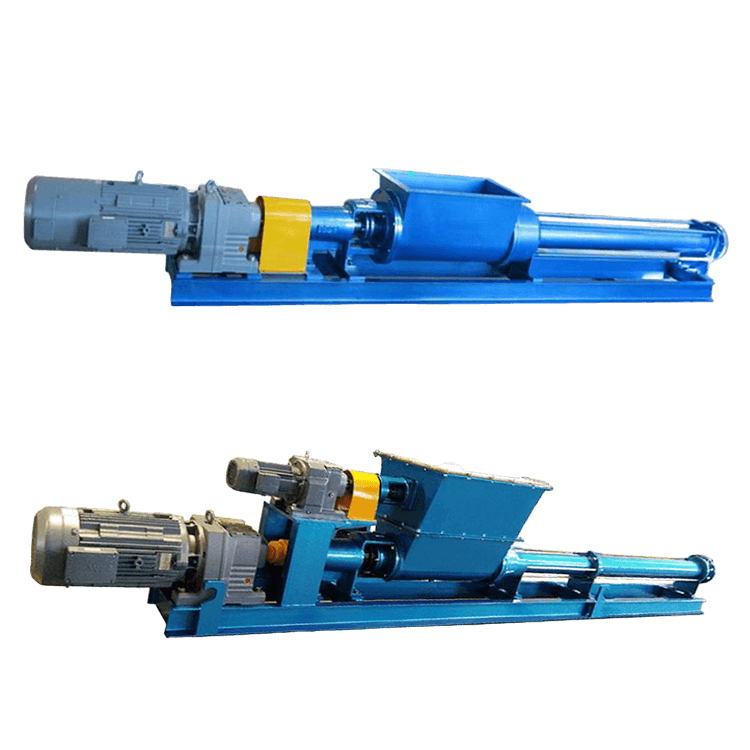

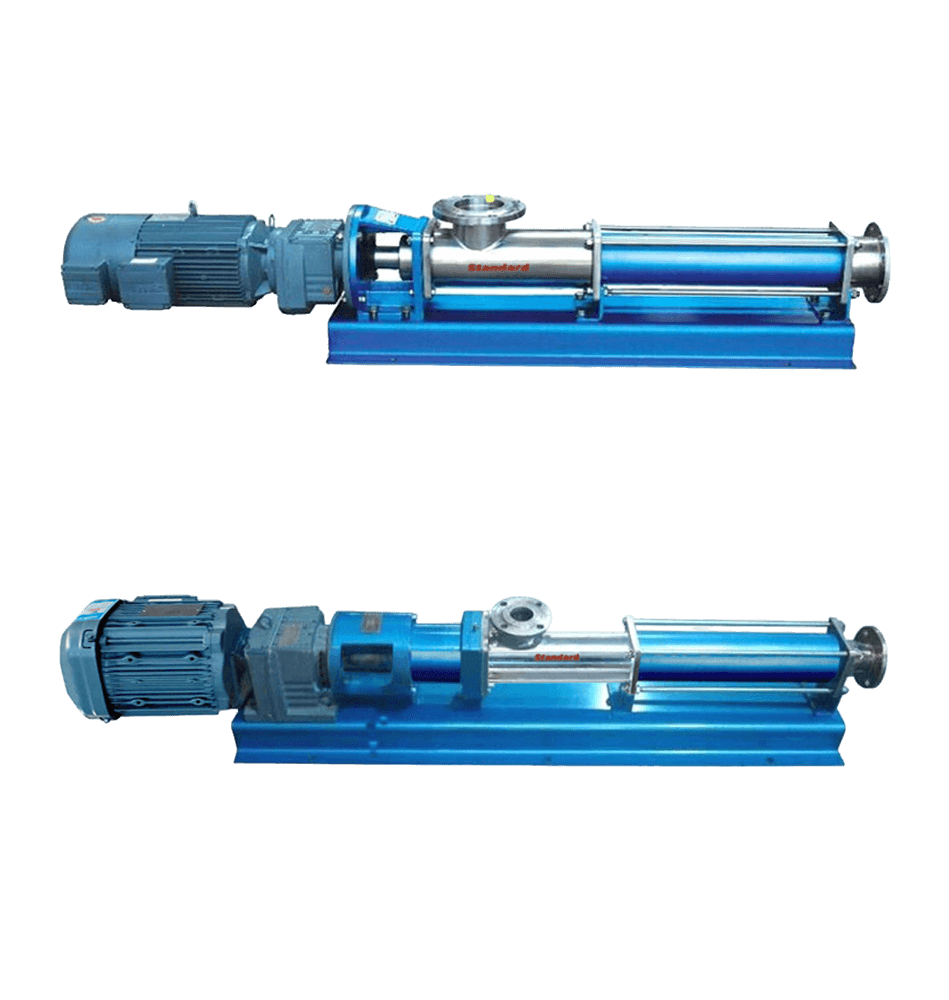

Vertical drum pump

Item Number:SD3cc–SD200cc

Dimensions(mm):L:305–705 ; ø:20–35

Weight:4.95–12kg

Output Pressure:18bar–24bar

Input Connection:G3/4″ G1″ G1 1/2″

Output Connection:G3/8″ G1″ G1 1/2″

Motor max(rpm)/min/:12-300rpm/min

recommended flow /second:0.13-0.5ml/s—50-20ml/s

Material Stator:FKM、EPDM、NBR

Material Screw:SUS304 SUS316

Producuts Name:

#vertical dosing drum pump# drum emptying pump #Barrel emptying pump #Emptying pump #emptying screw pump #drum pump #barrel pump #rotary drum pump #55 gallon drum pump #oil drum pump #barrel transfer pump #chemical drum pump #electric barrel pump #grease drum pump #barrel drum pump #rotary barrel pump #barrel with pump #pump for 55 gallon barrel #barrel pump for glue#

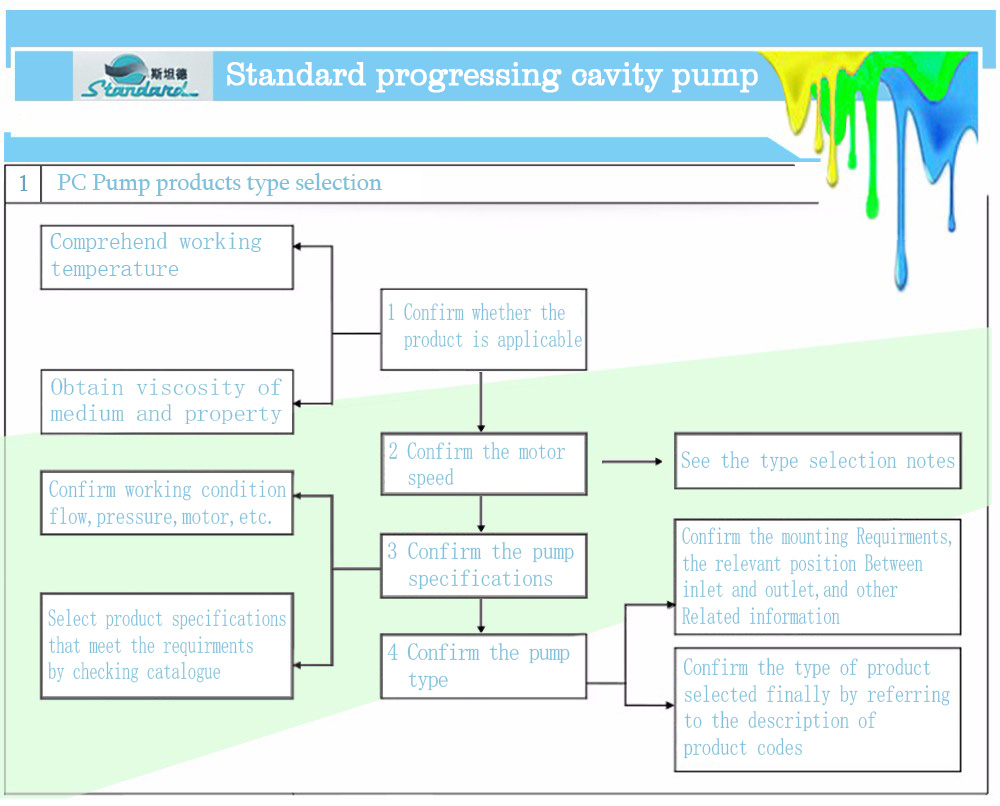

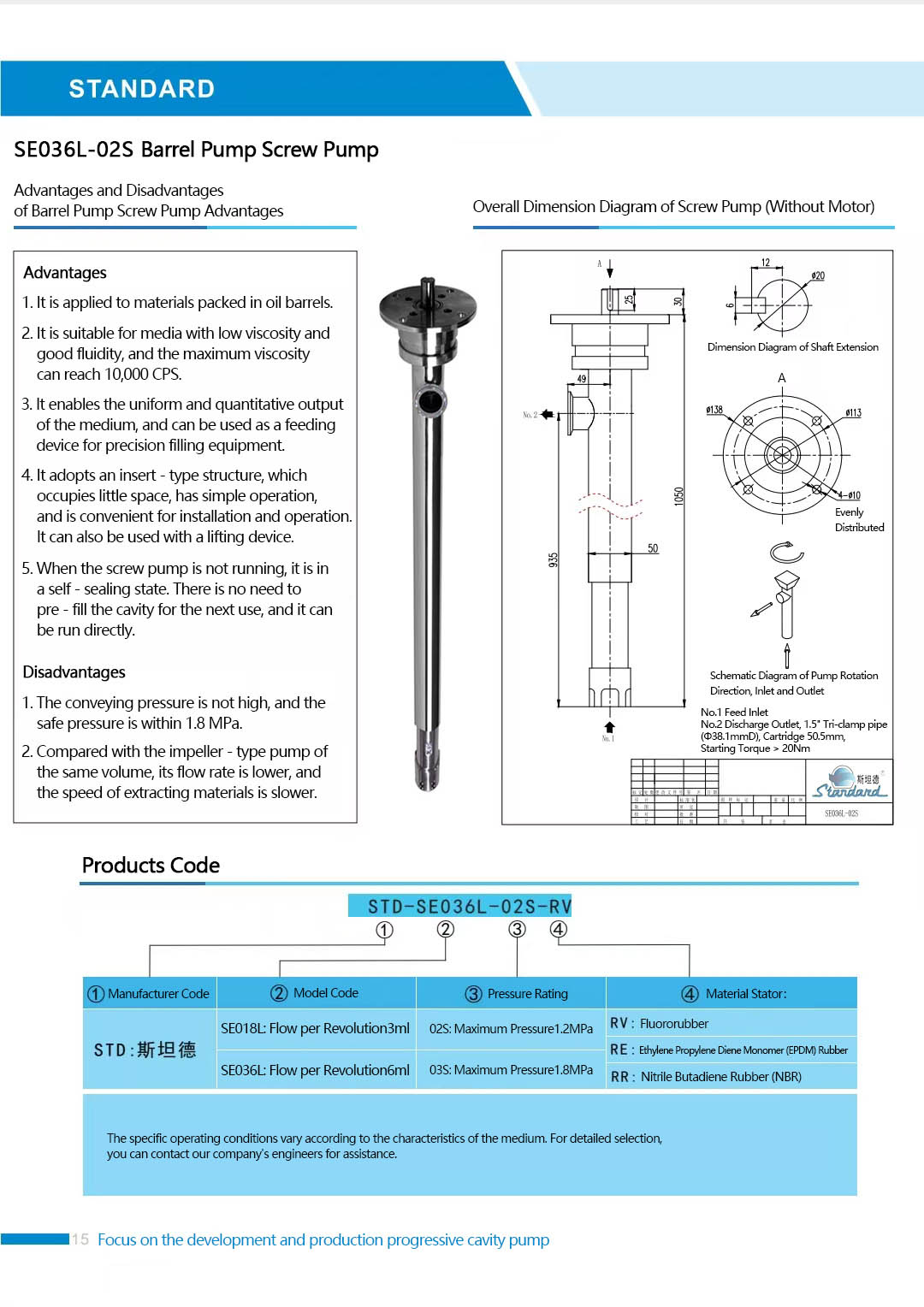

Functional description - How does a progressive cavity pump work?

The eccentric screw pumps belong to the rotating displacement pumps. This means that the liquid to be pumped is first fed into a pumping chamber and then displaced upwards from there. In concrete terms, this works by means of a rotating shaft in the inner pipe of the eccentric screw pump. This shaft with an eccentric screw at the lower end rotates in an oscillating manner against a stationary stator.

The helical geometry of the eccentric screw and the stator creates delivery spaces in which the corresponding medium is then displaced upwards from the lower pump inlet to the pump outlet. These eccentric worms are made of high-quality stainless steel and the stators of elastic material ( NBR white/black ,EPDM &FKM )

With progressive cavity pumps, the consistency and viscosity of the medium is also irrelevant for the flow rate, as the quantity to be pumped is only determined by the speed of the motor in combination with the pump. With a frequency converter, the flow rate can be controlled easily and precisely.

Progressive cavity pumps of Guangdong Standard Fluid Systems Company are suitable for pumping thin to high-viscosity fluids. The displacement pumps work with low turbulence at a constant pressure and provide for a gentle and pulsation-free operation. The SV progressive cavity pumps can be designed for industrial applications as well as for the pharmaceutical, food and cosmetic (hygienic) sectors. All progressive cavity pumps of SV series are mobile and stationary, consist of only a few components and are easy and quick to dismantle

Standard SV series vertical dosing drum pump technical parameters chart

| Art. No. | Allowable Speed | Optimum Speed | Recommended Amount of Glue | Output Pressure | Starting Torque |

| SV-0.5cc | 12-300rpm | 15-60rpm | 0.13-0.5ml/s | 24bar |

≥10nm |

| SV-1.5cc | 12-300rpm | 15-60rpm | 0.38-1.5ml/s | 18bar | ≥10nm |

| SV-3cc | 12-300rpm | 15-60rpm | 0.75-3ml/s | 18bar | ≥16nm |

| SV-6cc | 12-300rpm | 15-60rpm | 1.5-6ml/s | 18bar | ≥20nm |

| SV-12cc | 12-300rpm | 15-60rpm | 3-12ml/s | 18bar | ≥30nm |

| SV-24cc | 12-300rpm | 15-60rpm | 6-24ml/s | 18bar | ≥50nm |

| SV-48cc | 12-300rpm | 15-60rpm | 12-48ml/s | 18bar | ≥100nm |

| SV-96cc | 12-300rpm | 15-60rpm | 24-96ml/s | 18bar | ≥200nm |

| SV-200cc | 12-300rpm | 15-60rpm | 50-200ml/s | 18bar | ≥400nm |

Stardard SV series vertical dosing drum pump outline dimensional drawing

| Model No. | Size(A) | Size(B) | Inlet | Outlet | (C) Shaft diameter | (D)Pin | Weight(kg) |

| SV-0.5cc | 192 | 305 | G3/4“ | G3/8“ | 20 | 6*6 | |

| SV-1.5cc | 230 | 343 | G3/4“ | G3/8“ | 20 | 6*6 | |

| SV-3cc | 225 | 340 | G3/4“ | G3/8“ | 20 | 6*6 | |

| SV-6cc | 245 | 360 | G3/4“ | G3/8“ | 20 | 6*6 | |

| SV-12cc | 280 | 395 | G3/4“ | G3/8“ | 20 | 6*6 | |

| SV-24cc | 365 | 475 | G1“ | G1/2“ | 20 | 6*6 | |

| SV-48cc | 465 | 580 | G1 1/2“ | G1“ | 24 | 8*8 | |

| SV-96cc | 540 | 655 | G1 1/2“ | G1“ | 24 | 8*8 | |

| SV-200cc | 645 | 765 | G1 1/2“ | G1 1/2“ | 35 | 10*10 | 25 |

What are the special features of the SV progressive cavity pumps from Guangdong Standard Fluid Systems company?

The SV progressive cavity pumps have been developed with a special focus on easy, intuitive and fast disassembly and cleaning of the surfaces in contact with the media. Benefit from the sophisticated design, the progressive cavity pump can be disassembled quickly and effortlessly. Design methods for seals and transition components are completely eliminate or at least minimize the dead space. These features make it particularly suitable for use in the food, cosmetics or pharmaceutical industries.

Benefits of the SV progressive cavity pump:

High delivery pressure up to 15 bar due to positive displacement principle

Very easy and quick cleaning

Wide viscosity range can be covered

Low-turbulence and gentle delivery

Ideal for the pharmaceutical and food industry, due to low dead space construction

Can be used vertically and horizontally

A wide range of applications

A large selection of pre-configured variants is already available for the most common applications and areas of use. For specific needs, media or special applications, the pump can be customised from various modular components to meet your requirements.

For which liquids are Standard progressive cavity pumps particularly suitable?

The Standard progressive cavity pumps are powerful and at the same time gentle in their delivery, which is why many different liquids can be pumped with them. They are particularly suitable for the following media properties:

Abrasive; adhesive;aggressive;solids-containing and solids-free;low to high viscosity;non-lubricating and lubricating;shear sensitive;

Applicable fluids :

| Food: | Strawberry paste, Tomato paste, Mayonnaise, Hamburger patty ingredients, Sake lees, Miso paste, Candy, Honey, Butter, Cheese, Chocolate, Bread dough |

| Chemical: | Silicone resin, Epoxy resin, Urethane resin, Vaseline, Ointment, Paint, Pigment, Ink, Sealants, Putty, Glass paste |

| Automotive: | Grease, Adhesive |

| Cosmetics: | Beauty cream, Emulsion, Shampoo, Conditioner, Surfactant |

High demands are often placed on our progressive cavity pumps, also with regard to areas such as food, pharmaceutical and cosmetic products. For example, our pumps are also used in the production of food, beverages and liquid food or in the pharmaceutical and cosmetics sectors. For such environments, SV progressive cavity pumps are offered in special Food versions. They comply with all relevant regulations for hygienic pumps, are designed without dead space and can be reliably cleaned.

Food products (e.g. tomato paste, caramel, peanut butter, mayonnaise, nut nougat cream, chocolate, fats, glycerine, concentrates from fruits and vegetables)

Pharmaceutical & cosmetic products (e.g. Vaseline, ointments, hair and body care products, lip gloss, mascara, face masks).

We offer the following materials for the selection of our stators to match our progressive cavity pumps:

NBR white (acrylonitrile butadiene rubber) elastomer, max. 90°C, ideal for oils and fats – also suitable for foodstuffs.

FKM (fluororubber) elastomer, max. 120°C, very good chemical resistance – unsuitable for food.

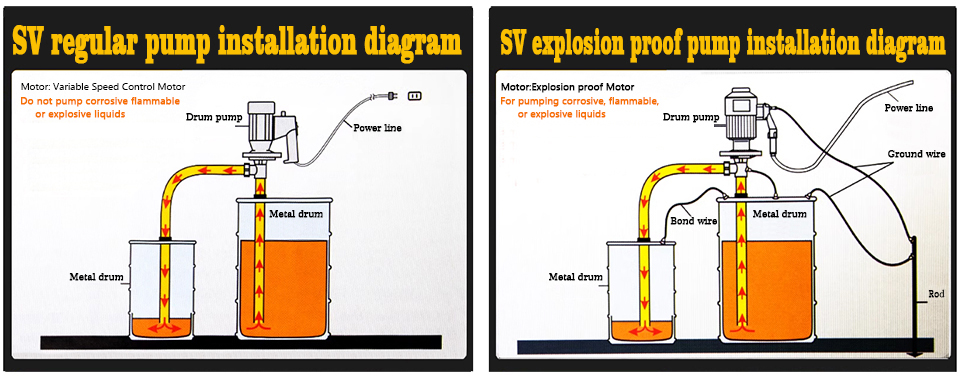

SV Explosion Installation diagramplo

1.Does Standard supply custom-made pumps ?

Yes, that’s our specialty. Our modular system with varying designs and material combinations allows customization for almost every application. This means we develop the optimal technical and economical solution for your requirements.

2.How fast can my Standard pump be delivered ?

Normally, standard pumps are delivered in 2 to 6 weeks. In urgent cases, delivery times between 2 to 6 days may be possible. Please contact us .Telephone/Whatsapp: 0086 -189 4242 4342

3.Buyers Attention

(1) Are Standard pumps allowed to run dry ?

No, the conveying elements are permanently in contact with one another, which means that dry running must be avoided in progressive cavity pumps. The Standard dry-running protection device offers reliable protection.

(2) At what temperatures can Standard pumps be used ?

Standard progressive cavity pumps can be used at temperatures from 0 °C to 90° C.

4.How to make an order for Standard screw pump ?

(1) Sample approval

(2) Client make 30-50% deposit after receiving our Proforma Invoice,

(3) Supplier start bulk production and finish production within agreed lead time

(4) Supplier arrange necessary documents and send them to client

(5) Client arrange balance payment

(6) Supplier arrange shipment , and send original documents or telex release the goods