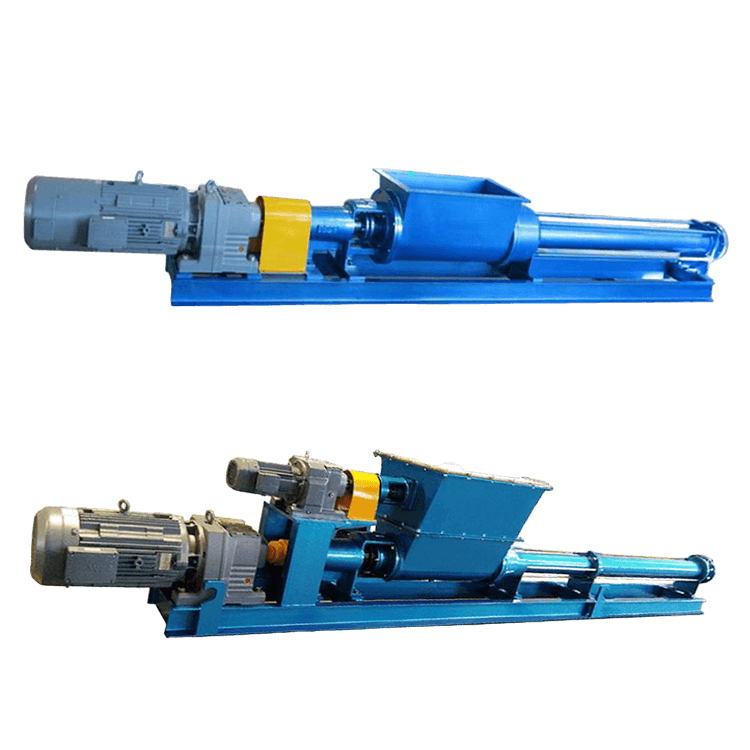

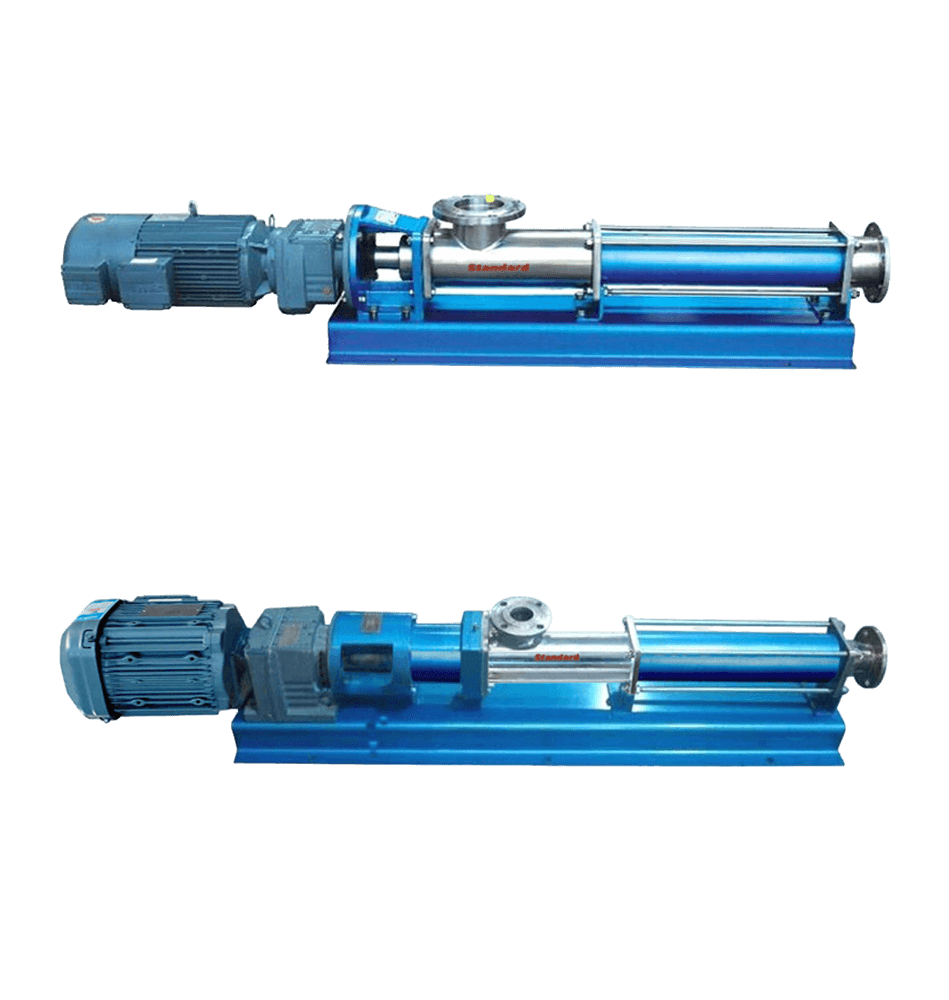

Adhesive Vertical pump

adhesive Vertical screw pump

Item Number:SVC-2600ml

Dimensions(mm):L: 407mm ø: 90mm

Weight:4.5kg

Output Pressure:1bar-3bar

Input Connection:

Output Connection:

Motor max(rpm)/min/: rpm/min

recommended flow /second: ml/s– ml/s

Material Stator:VITON、EPDM、NBR

Material Screw:SUS304 SUS316

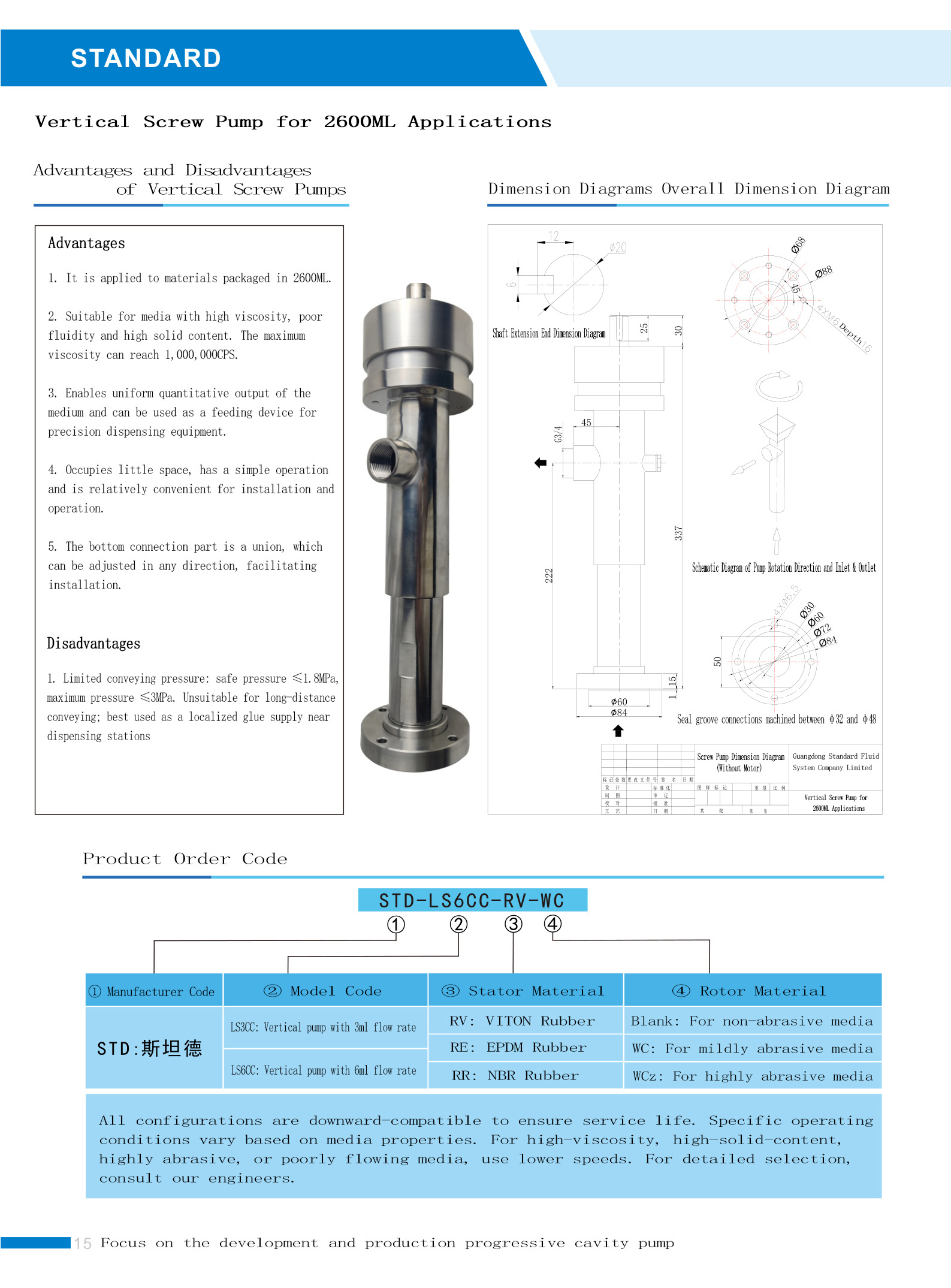

Description of fluid Vertical pump seriesproduct

Outstanding Performance:

(1). Continuous, volumetric dispense with high repeatability (2).Wide range of adjustable flow rates (3).Wear resistant and low maintenance (4). Available in different sizes to meet a wide range of applications

Unmatched Performance:

(1).High accuracy (2).High repeatability (3).Continuous dosing (4).Speed proportional (5).Low pulsation and shear (6).Well-suited for abrasive materials (7).Available in several volumes for application flexibility

Material Compatibility:

(1).Thermal Interface Materials (TIMs) (2).Silicones (3).Epoxy resin adhesives (4).Solder paste (5).Flux (6).Grease (7).Epoxies (8).Polyurethanes

Scope of Application

(1). Electronics Industry

(2). Semiconductor industry

(3). lcd/led

(4). PV Solar Energy industry

(5). Pharmaceutical Industry

(6). biochemical industry

(7). Laboratory

(8). optics and optoelectronics industry

(9). SMD/SMT

Medium viscosity chart

The endless piston principle?

(1)The functional principle of the Standard vertical pump is similar to that of an endless piston dispenser .

(2)The special conveying geometry enables continuous , pulsation – free dispensing flow . Reversing the direction of rotation ( suck – back function ) prevents dripping and leads to a controlled thread break of the material . Standard delivers high – precision and clean dispensing results .

(3)Particularly sensitive material with high viscosity and filers are treated gently due to the low shear stress and low pressures.

Our services :

(1). Our screw pump series products have reasonable price, quality service, professional inspection. Welcome to customize.

(2). we have a special quality Supervision Department to ensure the quality of mass production.

(3). If the product has quality problems, we will deal with it at he first time, find out the cause and take responsibility.

(4). If you are interested in our products and companies, please leave a message or email us , we will give you an answer within 24 hours

Why choose us ?

(1). Factory Direct Sales, no intermediate links, competitive price

(2). Our machines are imported from Europe, the original machine factory, the production of stable product quality, do not use low quality equipment.

(3). Ensure on-time delivery, we can provide the best quality of service control, transportation, documentation and so on.

(4). We provide samples and OEM services.

(5). We will reply to your enquiry within 24 hours.

(6). More than 20 years of experience in this industry business, and professional team, so that our customers feel relaxed and comfortable working with us in

(7). Please contact us by email and we will send you more information.

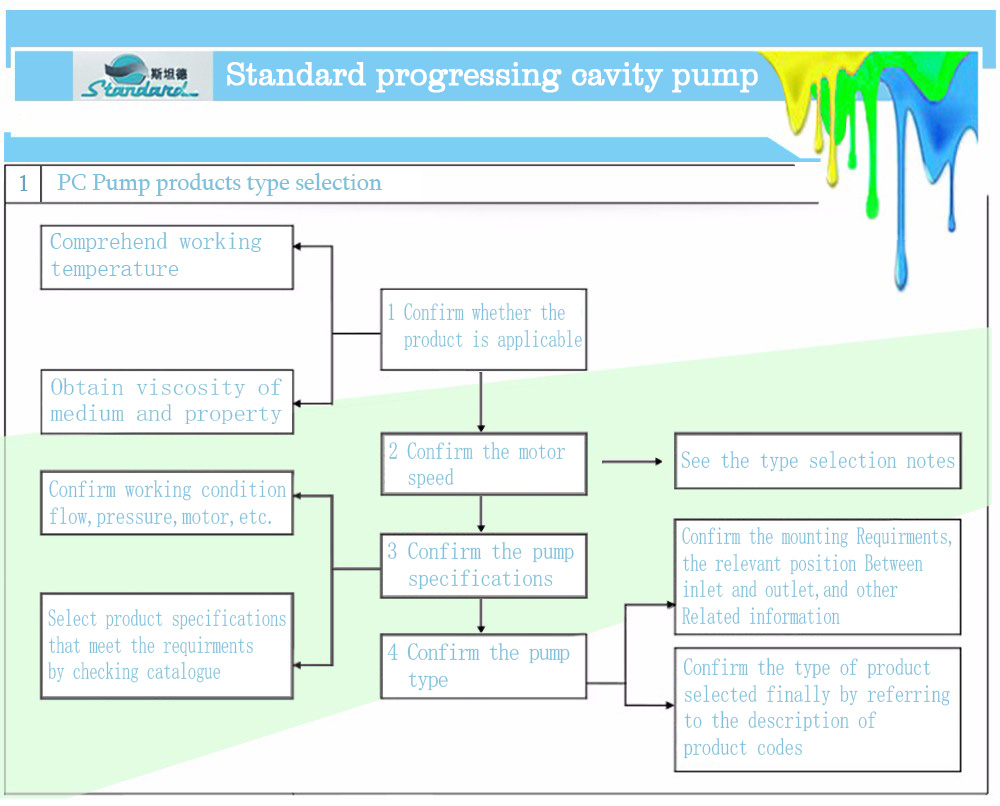

How to make an order for Standard progressive cavity pump ?

(1). Sample approval

(2). Client arrange 30-50% deposit after receiving our PI (pro forma invoice)

(3). We start bulk production and finish production within agreed lead time

(4). We send product photo and shipping documents to client

(5). Client arrange balance payment

(6). We arrange the delivery, and send original documents or telex release the goods