Coating PC pump for lithium industry

Coating pump for lithium industry

Item Number: CT08B-CT30B

Weight: 2.8-20kg

Input Connection:1″ pipe, clamp 50.5 — 2″ pipe, clamp 64

Volume per revolution:2-108ml/rev

Material Stator:EPDM PDFE

Material Screw:SUS304 SUS316

Products Name:

#Coating pump#Sealcoat pump#Epoxy pump#Teflon pump#coating dosing pump#coating pc pump#chemical industry coating pump#

Coated screw pump for lithium battery industry

In the lithium battery industry, Standard is specialized in the development and production of slurry conveying screw pumps, coating screw pumps, edge coating screw valves, with advantages including advanced technology, perfect structure, diverse forms, complete specifications, durable, is widely used in lithium battery industry multi-process. And obtained

It has won unanimous praise from leading enterprises in the industry. Standard has also become a stable supplier of many famous enterprises, and its products are exported to the United States, Germany, Japan, South Korea, Israel and other countries.

Pump for high-viscosity liquids and high-concentration slurries with excellent abrasion resistance and solvent resistance

For the lithium-ion battery manufacturing industry

Features

Achieves long life with materials that are excellent in wear resistance and solvent resistance.

A new slim casing with an internal volume reduced by about 30% is used.

Simple structure with few parts. It can be easily disassembled and cleaned in a short time.

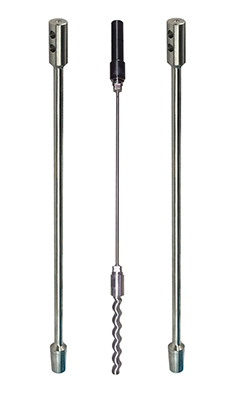

ROTOR | STATOR | JOINT PART | General spare parts for coating screw pump |

| stainless steel with excellent wear resistance, solvent resistance, and insulation are also available. | PTFE with excellent solvent resistance and EPDM/NBR/FFKM with excellent wear resistance are also available | A flexible rod with no sliding parts is used to reduce the number of parts and improve maintainability. | The Standard factory always has general spare parts for the special screw pump for the lithium battery industry of Standard brand and other screw pumps of other brands in the world |

|  |  |  |

Introduction to the current situation of lithium battery industry

With the vigorous development of the new energy industry, screw pumps are used in several key nodes in the current lithium battery process technology, and the current industry applications are highly dependent on imported brand products.

As a company specializing in the development and production of screw pumps, Standard has developed several specifications of screw pumps that can adapt well to the current industry applications, and the stability of the products is comparable to that of imported brand products, and has the advantages of faster delivery and better service.

Industry-applicable

For lithium-ion battery manufacturing, we currently have three series of products suitable for:

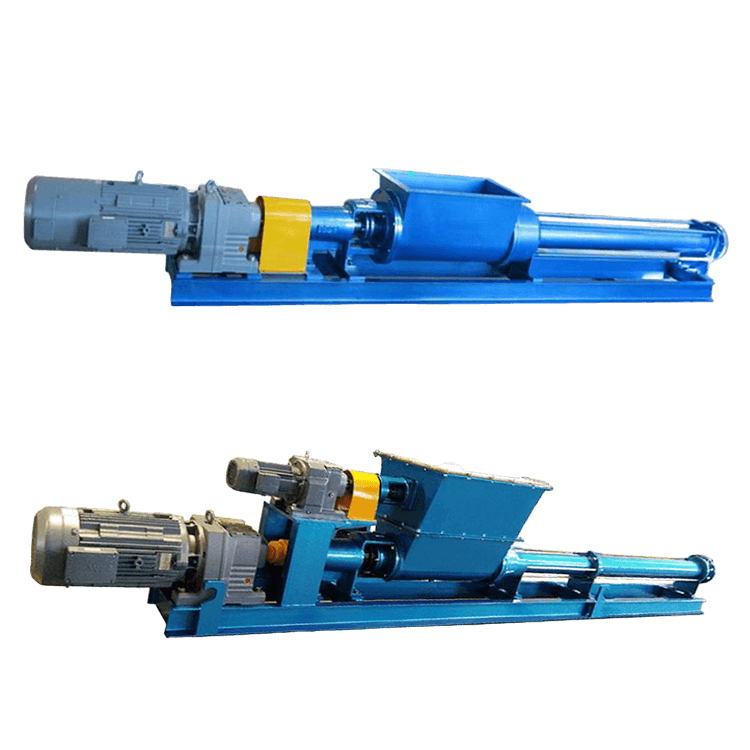

(1). Lithium battery slurry conveying screw pump

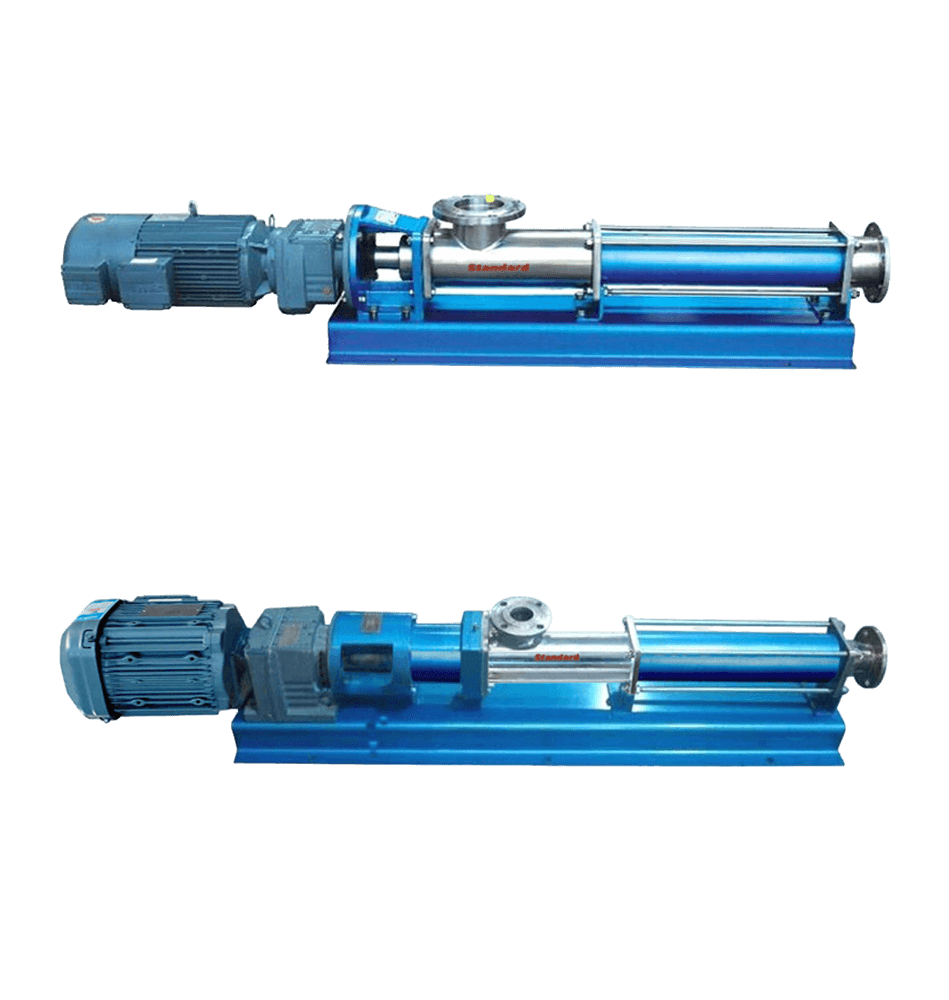

(2). Lithium battery coating screw pump

(3). Lithium battery edge coating screw valve

Process considerations

(1). Slurry conveying process: realize the slurry transfer with stable flow

The material can be conveyed stably and without shearing using the progressive cavity pump, and the conveying efficiency can be easily set by adjusting the speed of the progressive cavity pump.

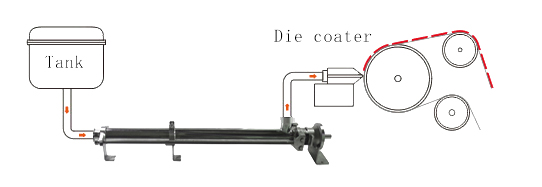

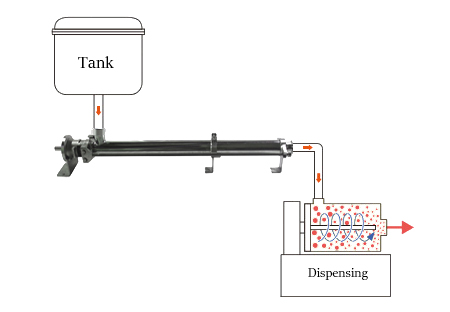

(2). Coating process: Achieve high-precision supply electrode material and homogenize the thickness of the coating film.

Using a progressive cavity pump allows the electrode material to pulsate-free and quantitatively supply to the coating die, this results in uniform coating on the diaphragm material. The conveying of the medium is not affected by viscosity, and even high-concentration slurries can be supplied without pulsation. The output flow can be easily adjusted over a wide range by simply controlling the rotation speed of the progressive cavity pump, helping to homogenize the thickness of the film layer in the precision film coating process.

(3). Edge coating process: realize a small amount of high-precision supply electrode material and uniformize the thickness of the coating film

The use of micro screw valves and micro coating dies can evenly coat the electrode material on the diaphragm material without pulsation. Suitable for coating electrode materials with narrow slits at the edge of the film. The conveying of the medium is not affected by viscosity, and even high-concentration slurries can be supplied without pulsation. The output flow rate can be precisely adjusted by controlling the rotation speed of the screw valve, helping to homogenize the thickness of the film layer in the precision film coating process. Through the return suction performance of the screw valve, it can achieve precise start and stop, uniform material cutting without residue, and intermittent coating can be realized and material can be saved.

(4). Vacuum degassing process: realize strong suction in high vacuum environment.

Through the attraction generated by the stator and rotor of the screw pump, even in a high vacuum environment, it can be strongly sucked in high-viscosity liquids or high-concentration slurries for quantitative transportation.

(5). Dispersion process: improve the uniformity of slurry.

Through the dispersion equipment, the liquid material is supplied quantitatively without pulsation, and the dispersion effect of microparticles is improved. Depending on the ability of the decentralized equipment, it is also easy to adjust the flow rate

Case study

High-precision supply of electrode materials and uniform coating film thickness

Even with high-concentration slurry, constant supply without pulsation is possible regardless of viscosity. Contributes to uniform film thickness in precision thin film coating. The amount of discharge can be easily adjusted over a wide range by simply controlling the rotation speed.

Powerful suction even under high vacuum conditions

Due to the suction force generated by the rotor/stator, high-viscosity liquids and high-concentration slurries can be strongly sucked and transferred in fixed amounts even under high-vacuum conditions.

Improve slurry uniformity

Liquid material is supplied to the disperser without pulsation, and the dispersion effect of fine particles is enhanced. It is easy to adjust the flow rate according to the capacity of the disperser.

Coating PC pump

The screw pump used in the lithium battery coating process mainly has the following specifications

Performance specification sheet

Art.No | Diameter A | Volume per revolution | Weight |

S T D – C T 0 8 B | 1″ pipe, clamp 50.5 | 2 . 0 | 2 . 8 |

S T D – C T 1 0 B | 1″ pipe, clamp 50.5 | 3 . 9 | 3 . 1 |

S T D – C T 1 5 B | 1.5″ pipe, clamp 50.5 | 1 4 | 1 2 |

S T D – C T 2 0 B | 1.5“ pipe, clamp 50.5 | 3 2 | 1 3 |

S T D – C T 2 5 B | 2“ pipe, clamp 64 | 7 0 | 1 9 |

S T D – C T 3 0 B | 2“ pipe, clamp 64 | 1 0 8 | 2 0 |

1. What products does Standard offer ?

Standard offers PC pump, PC pump accessories, and the global solution of the fluid system product.

The product range summary of Standard

Progressive cavity pumps for conveying and metering low to highly viscous media with or without solids

Macerators for macerating solid and fibrous components in the medium

Control systems for monitoring, regulating and controlling processes

Services: consulting, commissioning, maintenance, repairs and various service contracts

2. Does Standard supply custom-made pumps ?

Yes, this is our specialty, we customize different design and material combinations for each application’s modular system. This means that we develop the best technology and the most economical solution for your needs.

3. Can Standard spare parts be ordered online ?

Yes, Standard screw pumps and spare parts as well as other brands Universal accessories can be ordered online. For order please contact us.

4. How fast can my Standard pump be delivered ?

Normally, standard pumps are delivered in 2 to 6 weeks. In urgent cases, delivery times between 2 to 6 days may be possible. Please contact us ( Telephone/Whatsapp/Telephone: 0086 189 4242 4342 )

5. Product quality guarantee

According to the international standard, whole pump 1 year warranty, Spare parts 6 months warranty

6. Buyers Attention

(1). Are Standard pumps allowed to run dry ?

No, the conveying elements are permanently in contact with one another, which means that dry running must be avoided in progressive cavity pumps. The Standard dry-running protection device offers reliable protection.

(2). At what temperatures can Standard pumps be used ?

Standard progressive cavity pumps can be used at temperatures from 0 °C to 90° C.

7. Our services

(1). Our screw pump series products have reasonable price, quality service, professional inspection. Welcome to customize.

(2). we have a special quality Supervision Department to ensure the quality of mass production.

(3). If the product has quality problems, we will deal with it at he first time, find out the cause and take responsibility.

(4). If you are interested in our products and companies, please leave a message or email us, we will give you an answer within 24 hours

8. Why choose us ?

(1). Factory Direct Sales, no intermediate links, competitive price

(2). Our machines are imported from Europe, the original machine factory, the production of stable product quality, do not use low quality equipment.

(3). Ensure on-time delivery, we can provide the best quality of service control, transportation, documentation and so on.

(4). We provide samples and OEM services.

(5). We will reply to your enquiry within 24 hours.

(6). More than 20 years of experience in this industry business, and professional team, so that our customers feel relaxed and comfortable working with us in

(7). Please contact us by email and we will send you more information.

9. How to make an order for Standard pump ?

(1). Sample approval

(2). Client arrange 30-50% deposit after receiving our PI (pro forma invoice)

(3). We start bulk production and finish production within agreed lead time

(4). We send product photo and shipping documents to client

(5). Client arrange balance payment

(6). We arrange the delivery, and send original documents or telex release the goods